Environment

At Scotsman we take our position as worldwide market leader very seriously. After all, there are not many companies that can claim to be the global market leader for as long as we have. But now the markets that we trade in around the world are facing some serious issues. Issues that we at Scotsman feel we have a responsibility, as market leaders, to address. Leading by example so that our customers can continue to rely on our name 100%. We hope that you will find this explanation of the practical delivery of our environmental and sustainability positioning useful.

If however you require further clarification or assistance with the development or implementation of your own environmental policy, please do not hesitate to contact Hubbard Systems our UK representatives. They’re extremely knowledgeable and will be delighted to help you. Supplying the UK market, Scotsman machines are compliant with all current EU, UK and Global legislation as well as being engineered to the highest of hygiene standards

Scotsman EcoX and 2022 F-Gas Regulations

The new Scotsman EcoX range only use Natural Refrigerants, which are fully compliant with the F-Gas Regulations and have almost ZERO impact on both Ozone Depletion Concerns and Global Warming Concerns.

Natural Refrigerants are known as the “Gentle Five”. They are natural occurring, non-synthetic substances that can be used as cooling agents. These substances includes 1) hydrocarbons 2) carbon dioxide 3) ammonia 4) water and 5) air.

The new EcoX range of Scotsman ice makers have been developed using only the following Natural Refrigerants:

1. Hydrocarbons R290 (Propane)

2. Carbon Dioxide R744

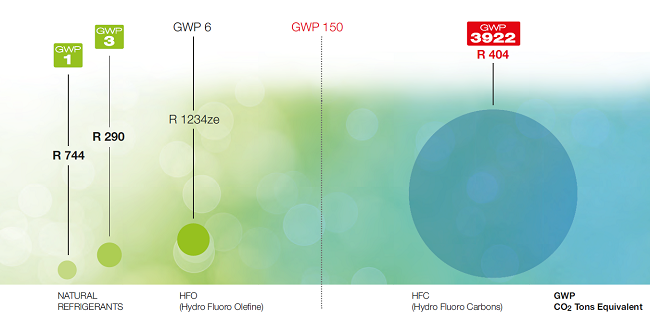

F-Gas Regulations – The European Union is committed to taking strong action to reduce the impact of climate change. The F Gas Regulation (517/2014) Directive, which will be fully implemented by 2022, aims to ban the use of harmful refrigerants with a high GWP (Global Warming Potential). The F Gas Regulation relates to two major worldwide protocols on climate change: the Montreal Protocol, covering Ozone Depletion Concerns and the Kyoto Protocol, covering Global Warning Concerns.

By 2022, only refrigerants with a GWP of 150 or less will be legal to use within the EU.

Low Carbon Footprints

Scotsman machines are a remarkably energy efficient way of producing high quality, hygienic ice. The new Scotsman 6 series, gourmet (supercube) ice makers incorporate a range of user friendly features aimed at reducing machine down time. Unique operator warning indicators ensure that routine maintenance schedules are adhered to. And, simple but often overlooked tasks including condenser air filter cleaning and scale removal are now straightforward two minute operator tasks, compared to traditional service call outs. This dedication to designed-in simplicity and practical maintenance ensures that Scotsman machines run at optimum efficiency during their working life. Consuming minimal energy in operation, reducing each machine’s carbon footprint. In support of your Environmental and Sustainability Policy Scotsman offer specific carbon footprint data for each Scotsman machine. For further information please call the Scotsman Technical Service on 01473 350021

Environmental Sustainability

WRAS – Water Regulations Advisory Scheme Each Scotsman ice maker supplied to the UK market is compliant with the WRAS, which exists to encourage the consistent interpretation and enforcement of regulations, for the prevention of waste, undue consumption, misuse, erroneous measurement or contamination of water. The WRAS has approved the water fittings and materials used in Scotsman machines as meeting the minimum requirements of the Water Supply (Water Fittings) Regulations 1999 in England and Wales, The Water Byelaws 2003 in Scotland and the Water Regulations in Northern Ireland. A panel of experts grants the approvals from the Water Supply Industry meeting regularly to review the fittings and the reports on any tests that have been undertaken. Scotsman machines incorporate a range of features that ensure water consumed during the ice production cycle is uncontaminated and remains potable. Particular attention has been paid to flushing of the ice making system after each production cycle to remove scale and impurities deposited from the water source. The Scotsman method of inverted spray ice production minimises waste and removes impurities through a gravity process resulting in an ice/water component that is proven to be purer than the constituent water supply.

PWD – Pumped Waste Discharge

Scotsman’s unique system allows the remote siting of Scotsman six series icemakers up to 1.5m below or up to 20m distant from existing drains. The PWD System, known as EASY-Fit is available on the most popular sizes of machines and can remove the need for extensive re-plumbing alterations in commercial premises or older refurbished locations. The system minimises disruption and damage to the existing fabric and environment.

RoHS – Restriction of Hazardous Substances

Also known as The Lead Free Directive this legislation bans the placing on the EU market of new electrical and electronic equipment containing more than agreed levels of lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) flame retardants. From the 1st January 2006, six months in advance of the 1st July 2006 deadline all Scotsman ice makers were RoHS compliant.

WEEE – Waste Electrical and Electronic Equipment

The UK WEEE regulations came into force on 2 January 2007 and support the RoHS Directive. WEEE is aimed at controlling the fastest growing waste stream in the UK and will reduce the amount of electrical and electronic waste going to landfill, whilst increasing recovery and recycling rates. There are certain requirements for WEEE relating to:

1. Separate collection, disposal and recycling

2. Standards for its treatment at authorised facilities

3. Collection, recycling and recovery targets

All Scotsman Ice Machines were fitted with the crossed out wheelie bin symbol during 2006, well before the 1st April 2007 deadline set by UK Government’. Scotsman and its UK distributor will ensure that ice making equipment classified as either historic WEEE and future WEEE will be dealt with under the business to business requirements of the directive. You can agree to transfer obligations for WEEE that is being replaced, or for new EEE when it becomes WEEE and is discarded. This agreement is offered as part of our normal contract negotiations, and as responsible manufacturers we are pleased to acknowledge that this arrangement can benefit both parties. Scotsman Ice Machines are manufactured in compliance with the following standards and QC qualifications

Low Carbon Footprints

Scotsman machines are a remarkably energy efficient way of producing high quality, hygienic ice. The new Scotsman 6 series, gourmet (supercube) ice makers incorporate a range of user friendly features aimed at reducing machine down time. Unique operator warning indicators ensure that routine maintenance schedules are adhered to. And, simple but often overlooked tasks including condenser air filter cleaning and scale removal are now straightforward two minute operator tasks, compared to traditional service call outs. This dedication to designed-in simplicity and practical maintenance ensures that Scotsman machines run at optimum efficiency during their working life. Consuming minimal energy in operation, reducing each machine’s carbon footprint. In support of your Environmental and Sustainability Policy Scotsman offer specific carbon footprint data for each Scotsman machine. For further information please call the Scotsman Technical Service on 01473 350021

Environmental Sustainability

WRAS – Water Regulations Advisory Scheme Each Scotsman ice maker supplied to the UK market is compliant with the WRAS, which exists to encourage the consistent interpretation and enforcement of regulations, for the prevention of waste, undue consumption, misuse, erroneous measurement or contamination of water. The WRAS has approved the water fittings and materials used in Scotsman machines as meeting the minimum requirements of the Water Supply (Water Fittings) Regulations 1999 in England and Wales, The Water Byelaws 2003 in Scotland and the Water Regulations in Northern Ireland. A panel of experts grants the approvals from the Water Supply Industry meeting regularly to review the fittings and the reports on any tests that have been undertaken. Scotsman machines incorporate a range of features that ensure water consumed during the ice production cycle is uncontaminated and remains potable. Particular attention has been paid to flushing of the ice making system after each production cycle to remove scale and impurities deposited from the water source. The Scotsman method of inverted spray ice production minimises waste and removes impurities through a gravity process resulting in an ice/water component that is proven to be purer than the constituent water supply.

PWD – Pumped Waste Discharge

Scotsman’s unique system allows the remote siting of Scotsman six series icemakers up to 1.5m below or up to 20m distant from existing drains. The PWD System, known as EASY-Fit is available on the most popular sizes of machines and can remove the need for extensive re-plumbing alterations in commercial premises or older refurbished locations. The system minimises disruption and damage to the existing fabric and environment.

RoHS – Restriction of Hazardous Substances

Also known as The Lead Free Directive this legislation bans the placing on the EU market of new electrical and electronic equipment containing more than agreed levels of lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) flame retardants. From the 1st January 2006, six months in advance of the 1st July 2006 deadline all Scotsman ice makers were RoHS compliant.

WEEE – Waste Electrical and Electronic Equipment

The UK WEEE regulations came into force on 2 January 2007 and support the RoHS Directive. WEEE is aimed at controlling the fastest growing waste stream in the UK and will reduce the amount of electrical and electronic waste going to landfill, whilst increasing recovery and recycling rates. There are certain requirements for WEEE relating to:1. Separate collection, disposal and recycling2. Standards for its treatment at authorised facilities3. Collection, recycling and recovery targetsAll Scotsman Ice Machines were fitted with the crossed out wheelie bin symbol during 2006, well before the 1st April 2007 deadline set by UK Government’. Scotsman and its UK distributor will ensure that ice making equipment classified as either historic WEEE and future WEEE will be dealt with under the business to business requirements of the directive. You can agree to transfer obligations for WEEE that is being replaced, or for new EEE when it becomes WEEE and is discarded. This agreement is offered as part of our normal contract negotiations, and as responsible manufacturers we are pleased to acknowledge that this arrangement can benefit both parties. Scotsman Ice Machines are manufactured in compliance with the following standards and QC qualifications