Integral drain pump gives flexibility in siting.

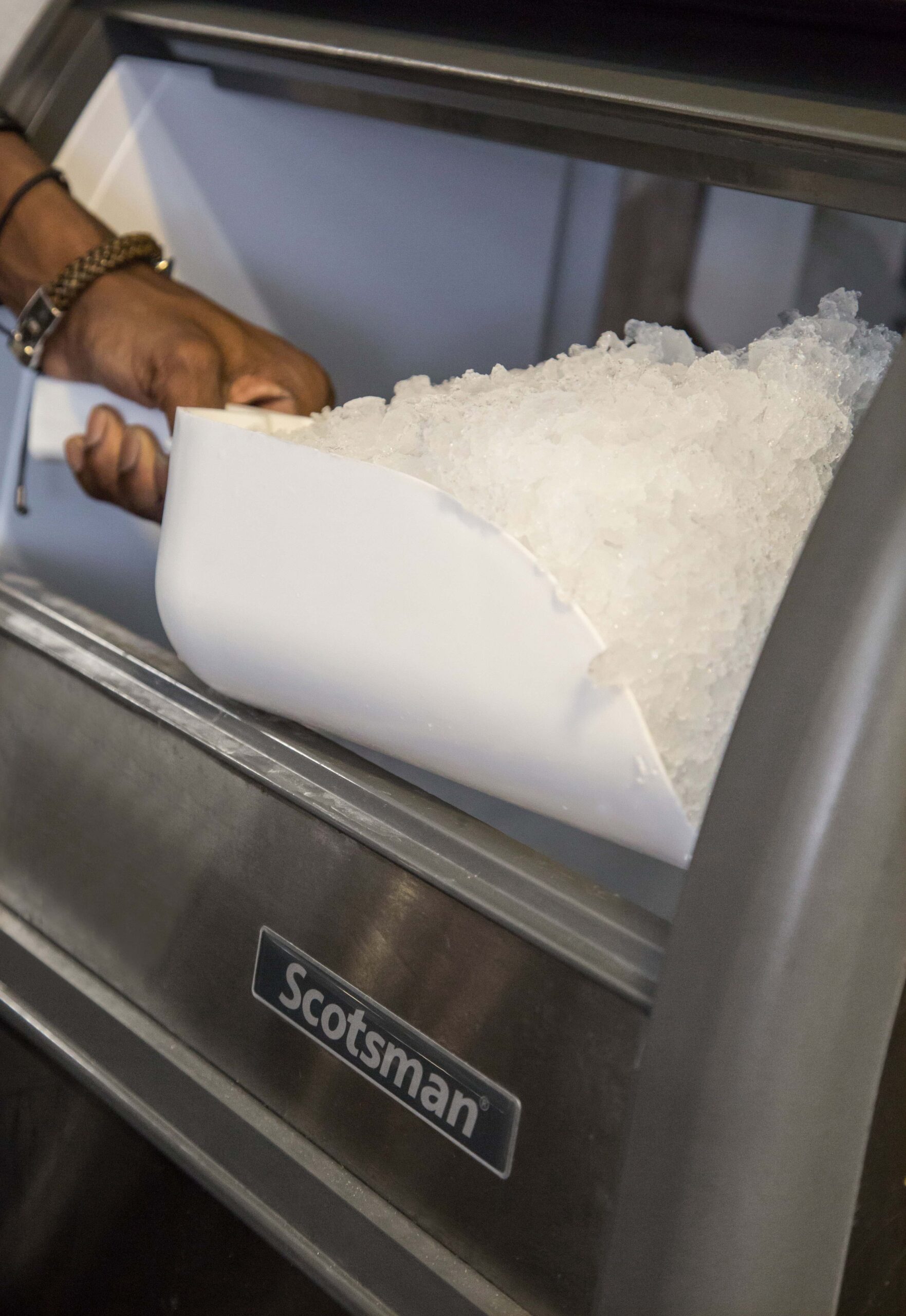

Flake ice is widely used in the medical, laboratory and sports science sectors. What these sectors share is the requirement for reliable supply of consistent ice that chills effectively and quickly. Scotsman has relaunched its EF Series of dedicated flake icemakers with a choice of compact, self-contained machines offering production rates of up to 200kg every 24 hours.

Flake ice is widely used in the medical, laboratory and sports science sectors. What these sectors share is the requirement for reliable supply of consistent ice that chills effectively and quickly. Scotsman has relaunched its EF Series of dedicated flake icemakers with a choice of compact, self-contained machines offering production rates of up to 200kg every 24 hours.

The Scotsman range is distributed in the UK by ice maker specialist company Hubbard Systems.

One key issue with ice machines is the need to position them near drains, which can cause installation problems in some sites. Scotsman has overcome this with the EF Series, which features an integral drain water pump. This gives much more flexibility in terms of where the machines can be sited, since they can be as much as 15 metres from the drain.

Meanwhile the EF’s front access condenser air filter means cleaning the filter is an easy, do-it-yourself task that saves time and money while increasing the life of the machine.

Meanwhile the EF’s front access condenser air filter means cleaning the filter is an easy, do-it-yourself task that saves time and money while increasing the life of the machine.

The EF103 is the smallest model in the range. It produces 108kg per day and has an integral storage bin capable of holding up to 30kg of flake ice. Despite this capacity, the EF103 measures just 592mm wide by 622mm deep and 1077mm high, so it fits under a worktop or lab bench easily.

Hubbard Systems also offers Scotsman’s larger, modular ice makers, offering daily production rates right up to 2,500kg, as well as a wide range of hygienic ice transport systems, so that a central machine can supply multiple areas.