Friulinox RBS-121-SA

Ready blast chiller/freezer. Takes up to 12x 1/1GN or EN1 trays. 65Kg chilling and 45Kg freezing capacity.

Ideal for Restaurants, Pubs, Hotels, and Food Manufactures

Max Tray Capacity

12x 1/1GN or EN1

![]()

Blast Chilling & Freezing

READY

Ready blast chiller/freezer. Takes up to 12x 1/1GN or EN1 trays. 65Kg chilling and 45Kg freezing capacity.

Ideal for Restaurants, Pubs, Hotels, and Food Manufactures

| Model |

Friulinox RBS-121-SA |

| Dimensions (W x D x H) |

790 x 870 x 1810 mm |

| Yield per cycle +90/+3°C |

65 Kg |

| Yield per cycle +90/-18°C |

45 Kg |

| Tray capacity |

12x 1/1GN or EN1 trays (65mm) |

| Refrigeration |

R452a |

| Cooling power |

1940 W |

| Cooling method |

Air cooled (water or remote on request) |

| Voltage |

400v / 50hz / 3ph |

| Fuse / CB rating |

See spec sheet |

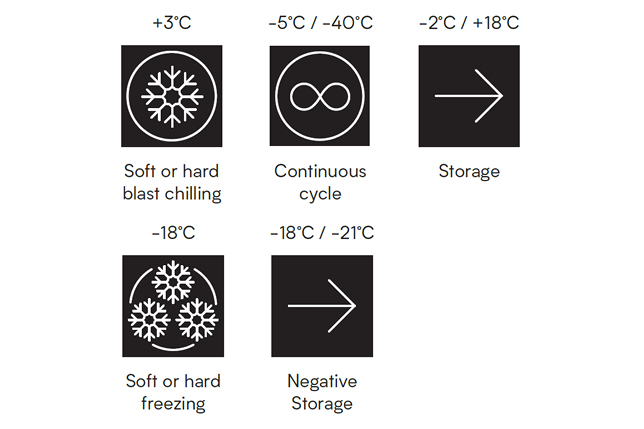

Functions of the Ready range

- Soft or hard chilling to +3°C

- Soft or hard freezing to -18°C

- Continuous Cycle from -5°C to -40°C

- Storage either positive (-2°C / +18°C) or negative (-18°C / -21°C)

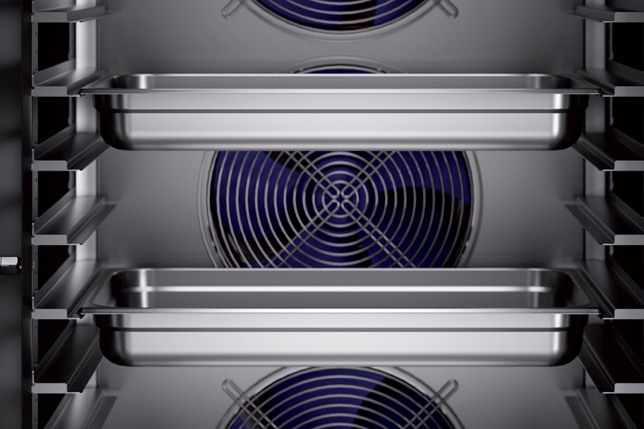

Flexible tray configuration

The Ready range of cabinets allow you to blast chill/freeze food in either full size 1/1 Gastronorm trays or standard EN1 baking grids (600x400mm) at the same time without the need for any additional or special racking.

Features of the Friulinox RBS-121-SA include:

External construction

• 0.8 mm-thick stainless steel external sides and door (Scotch-Brite satin finish)

• Stainless steel internal coating with fully rounded corners

• Die-moulded and leakproof internal base

• Full-length flush ergonomic handle

• 1 mm-thick stainless steel top (Scotch-Brite satin finish)

• HCFC-free high-density polyurethane foam insulation (approx. 42 kg/m³)

• Anti-condensation heating element situated on the body frame, under the stop

• Magnetic seal on 4 sides of the door

• Stainless steel exterior (Scotch-Brite satin finish)

• Indirect-flow electric fans – made of composite material – on the product

• Cooling capacity expressed at evaporation temperature -25°C and condensation temperature at +45°C

Interior features

• Quick-release heated core probe with 4 measuring points

• Removable stainless steel double-track guides (GN-EN), equipped with an anti-tip system. (Grids sold separately)

• Side guide-supporting uprights with 18 mm-pitch holes.

Controls

• 5″ high-definition TOUCH display

• Pictogram and text-identifiable processes

• USB connection for uploading and downloading data/recipes

• Compressor-protecting automatic-reset thermal circuit breaker

• Wifi connectivity (optional)

Performance Tested to European Standard EN17032

All Friulinox Blast Chiller and Freezers are fully tested using a ‘real world’ product to ensure all capacity and performance figures are achievable by the operator.

Performance – the performance test was performed with mashed potatoes in a GN1/1 H40 mm tray, with the mashed potatoes being 35 mm thick, equal to ~5 kg per tray, with blast chiller in a room measured at 30°C.

Chilling consumption – The specific blast chilling consumption expressed in kWh/kg was taken starting with an average mashed potato temperature of 65°C, arriving at +10°C at the end of blast chilling and in less than 120 minutes.

Freezing consumption – The specific consumption in quick deep freezing expressed in kWh/kg was taken starting at an average mashed potato temperature of 65°C, arriving at -18°C at the end of deep freezing and in less than 270 minutes.

Please download the specification sheet for full details of this specific machine.