Friulinox SBM-122-HA

Submarine multifunction blast freezer. 22x 1/1GN or EN1 trays, 100Kg chilling and 70Kg freezing capacity.

Chill, freeze, slow cook, prove, pasterurise, and more...

Max Tray Capacity

22x 1/1GN or EN1

![]()

Multi-Function

SUBMARINE

Submarine multifunction blast freezer. 22x 1/1GN or EN1 trays, 100Kg chilling and 70Kg freezing capacity.

Chill, freeze, slow cook, prove, pasterurise, and more...

| Model |

Friulinox Submarine SBM-122-HA |

| Dimensions (W x D x H) |

1100 x 1080 x 1860 mm |

| Yield per cycle +90/+3°C |

100 Kg |

| Yield per cycle +90/-18°C |

70 Kg |

| Tray capacity |

22x 1/1GN or EN1 trays (65mm) |

| Refrigeration |

R452a |

| Cooling power |

3619 W |

| Cooling method |

Air cooled (water or remote on request) |

| Voltage |

400v / 50hz / 3ph |

| Electric power / consumption |

5.76 kWh / 15.4 amps |

| Additional info |

Requires water & waste connections |

| Recommended water filter |

3M HF20-S |

… and it blast chills and freezes!

Submarine is the first truly multifunctional blast chiller on the market. It’s huge operating temperature range goes from -40ºC to +85ºC. This allows you to do all of the usual blast chilling jobs but with the ability to do a whole lot more…

You can blast chill/freeze, use it as a storage fridge/freezer, freeze to -40ºC to kill parasites in raw meat and fish, heat it to +65C to pasteurise, slow cook in bulk up to +85ºC, prove and retard dough, melt chocolate and crystalise, dehydrate products, culture yogurt, and safely thaw.

Programs can be linked together to give a complete, cook, chill, store and serve solution for your kitchen.

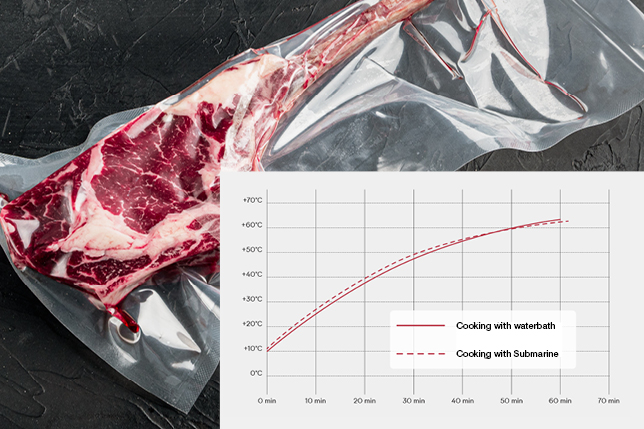

Slow cooking in bulk

As many professionals know, the best cooking results of low-temperature vacuum-sealed foods are obtained by cooking them in a water bath. Friulinox laboratories’s research gave us Submarine. Which, thanks to the Submarine’s fine tuning, replicates, as shown in the graph, exactly the same results obtained with a water bath. Perfect homogeneity in the increase in cooking temperatures with almost the same times.

Once the cooking process has finished, Submarine can either automatically chill the product for safe storage, or hold at a temperature ready to serve.

Bakers and confectioners

Submarine’s precise humidity and temperature controls allow operators to carefully prove yeast based doughs, or retard the process and delay the operation until its needed. Bakers can load the unit the night before and at a predetermined time the Submarine will automatically start the proving cycle ensuring the dough is ready to bake when they arrive the next morning.

Submarine’s active humidity control ensures delicate products like chocolate can be carefully melted without over heating to damage due to moisture. Ideal for pastry chefs who need to work in bulk.

Features of the Friulinox SBM-122-HA include:

External construction

• 0.8 mm-thick stainless steel external sides and door (Scotch-Brite satin finish).

• 1 mm-thick stainless steel top (Scotch-Brite satin finish).

• Stainless steel internal coating with fully rounded corners

• Die-moulded and leakproof internal base.

• Anti-condensation heating element located on the box under the magnetic seal stop.

• Strongbox ergonomic handle.

• 0.8 mm-thick stainless steel door (Scotch-Brite satin finish).

• HCFC-free high-density polyurethane foam insulation (approx. 42 kg/m³).

• Magnetic seal on 4 sides of the door.

• Stainless steel exterior (Scotch-Brite satin finish).

• Indirect-flow electric fans – made of composite material – on the product.

• Patented chamber humidity-injecting system.

• Cooling capacity expressed at evaporation temperature -25°C and condensation temperature at +45°C

Interior features

• Quick-release heated core probe with 4 measuring points.

• Side guide-supporting uprights with 18 mm-pitch holes.

Controls

• 7” high-definition FULL TOUCH display.

• Control-activated chamber sanitisation system with active ions (HI-GIENE).

• Compressor-protecting automatic-reset thermal circuit breaker.

• Photo-identifiable processes.

• USB connection for uploading and downloading data/recipes.

• Standard connectivity.

Performance Tested to European Standard EN17032

All Friulinox Blast Chiller and Freezers are fully tested using a ‘real world’ product to ensure all capacity and performance figures are achievable by the operator.

Performance – the performance test was performed with mashed potatoes in a GN1/1 H40 mm tray, with the mashed potatoes being 35 mm thick, equal to ~5 kg per tray, with blast chiller in a room measured at 30°C.

Chilling consumption – The specific blast chilling consumption expressed in kWh/kg was taken starting with an average mashed potato temperature of 65°C, arriving at +10°C at the end of blast chilling and in less than 120 minutes.

Freezing consumption – The specific consumption in quick deep freezing expressed in kWh/kg was taken starting at an average mashed potato temperature of 65°C, arriving at -18°C at the end of deep freezing and in less than 270 minutes.

Please download the specification sheet for full details of this specific machine.